On Digital DIY, and its place in India

A couple of weeks ago I gave a talk at the Swatantra17 conference in Trivandrum, Kerala, about “Open, Digital DIY manufacturing across countries and cultures” (here are abstract and slides) ). This is a guest post by Mrs Revathi Kollegala, social entrepreneur and collaborative economy advocate, containing her feedback to my slides.

The text in square brackets is comments or extra information by me.

An interesting vision

You are so right with your observations [in the slides], especially as it relates to India. I’d never thought of 3-D printers for Digital DIY manufacturing in that respect - it’s a super interesting vision. It’s an uphill battle here but I’m working on getting a team together to set up open participatory collaborative platforms.

I’m “guilty” of linking DIY manufacturing with the first world Western-style consumerism. I hadn’t thought of it as a feasible means to enable low cost, community-owned manufacturing for common wants. The slides are very articulate. They made me think of practical ways to collaborate with existing projects and achieve this vision faster than I thought possible.

Yes, you are right that the slides don’t account for how important the labor market is in India [see notes below]. Low-cost labor (apart from agriculture) is the means of livelihood for a huge proportion of low income population in India. The danger in industrial automation (and DIY manufacturing) is that they could take away their livelihoods. On the other hand, if adopted in the right way, DIY manufacturing can be an opportunity to convert the existing jobs into better paying jobs and fight the loss of jobs due to industrial automation.

There are two more aspects that are very India-specific and I don’t see considered in the slides:

- The consumption pattern in India is unique in some aspects. Here is a fairly good overview. The rural to urban migration, digitization speeded up due to demonetization and the Aadhaar project and lagging governmental rules and regulations create a unique market landscape. Will the consumer in India be more open to a low cost 3D printed cellphone than the expensive ones advocated by celebrities on TV and on billboards? The answer is, I think, it depends. Different strategies are needed to reach the different consumer regions and income groups.

- Specifically for DIY manufacturing, the government initiative to establish “Tinkering labs” is very relevant. These are government-sponsored makerspaces and could potentially become Fablabs.

Notes by Marco

First of all, thanks to Mrs Kollegala for her precious feedback, and to everybody else who will provide theirs. In the next days, I will add more reports and comments about what I did and learn in India. Follow me by RSS or Twitter to stay tuned!

With respect to the “labor market”: the very first feedback I received in India about my talk, which when shared with Mrs Kollegala prompted her comments above, is as obvious as it is important AND forgotten, among “first world” advocates of distributed digital manufacturing. Using those techniques to make some unique object only makes sense when you cannot have it done manually at a lower price. Outside of “first world” countries, if you want a custom piece of furniture, art, etc… drawing a sketch and handing it to some skilled craftperson is very likely much cheaper (both money- and time-wise) than (learning to) use a 3D printer to achieve the same result. Of course, this is not always true (see #3 below).

If you are interested in much more practical summaries and advice on the topics of community-owned manufacturing and also of how it may interact with loss of jobs…

- please have a look at the DiDIY manual.

- another great “entry-point” for beginners to the overall topic is the DiDIY Creative Society Manifest.

- again on the general “DiDIY manufacturing is useless when labour cost is low” issue. This is very often true, especially in developing countries… except in one hugely important set of cases, that is: relatively high-tech objects that are essential in rural, very poor communities, but simply cannot be produced by manual, unskilled labor.

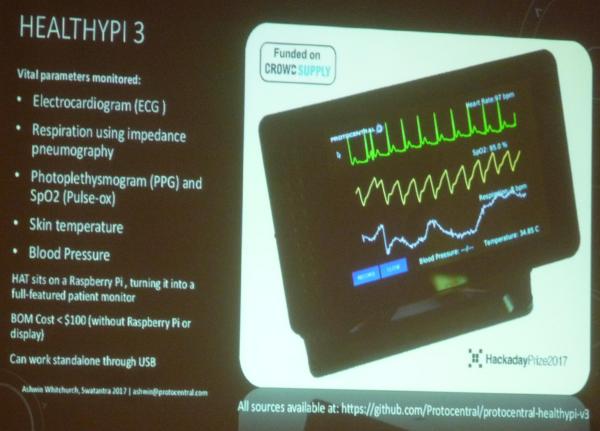

Efficient water filters, drones to efficiently monitor forest fires, but above all lifesaving MEDICAL devices like this (Made in India!) heart monitoring board:

… all at much lower costs than commercial equivalents.. this is stuff that would greatly improve life quality in poor villages, and can only be produced with digital technologies and digital manufacturing tools. Wouldn’t it be great if fablabs in developing countries were able to use their spare capacity to produce such goods?

Who writes this, why, and how to help

I am Marco Fioretti, tech writer and aspiring polymath doing human-digital research and popularization.

I do it because YOUR civil rights and the quality of YOUR life depend every year more on how software is used AROUND you.

To this end, I have already shared more than a million words on this blog, without any paywall or user tracking, and am sharing the next million through a newsletter, also without any paywall.

The more direct support I get, the more I can continue to inform for free parents, teachers, decision makers, and everybody else who should know more stuff like this. You can support me with paid subscriptions to my newsletter, donations via PayPal (mfioretti@nexaima.net) or LiberaPay, or in any of the other ways listed here.THANKS for your support!